WS3

Ovenbird: Automated toolpath design for 3D concrete printing

Learning Objectives

1. We will briefly review the form-finding methods employed in 3D-printed structures. Participants will learn to use the form-finding method of Polyhedral Graphic Statics using Polyframe 2.

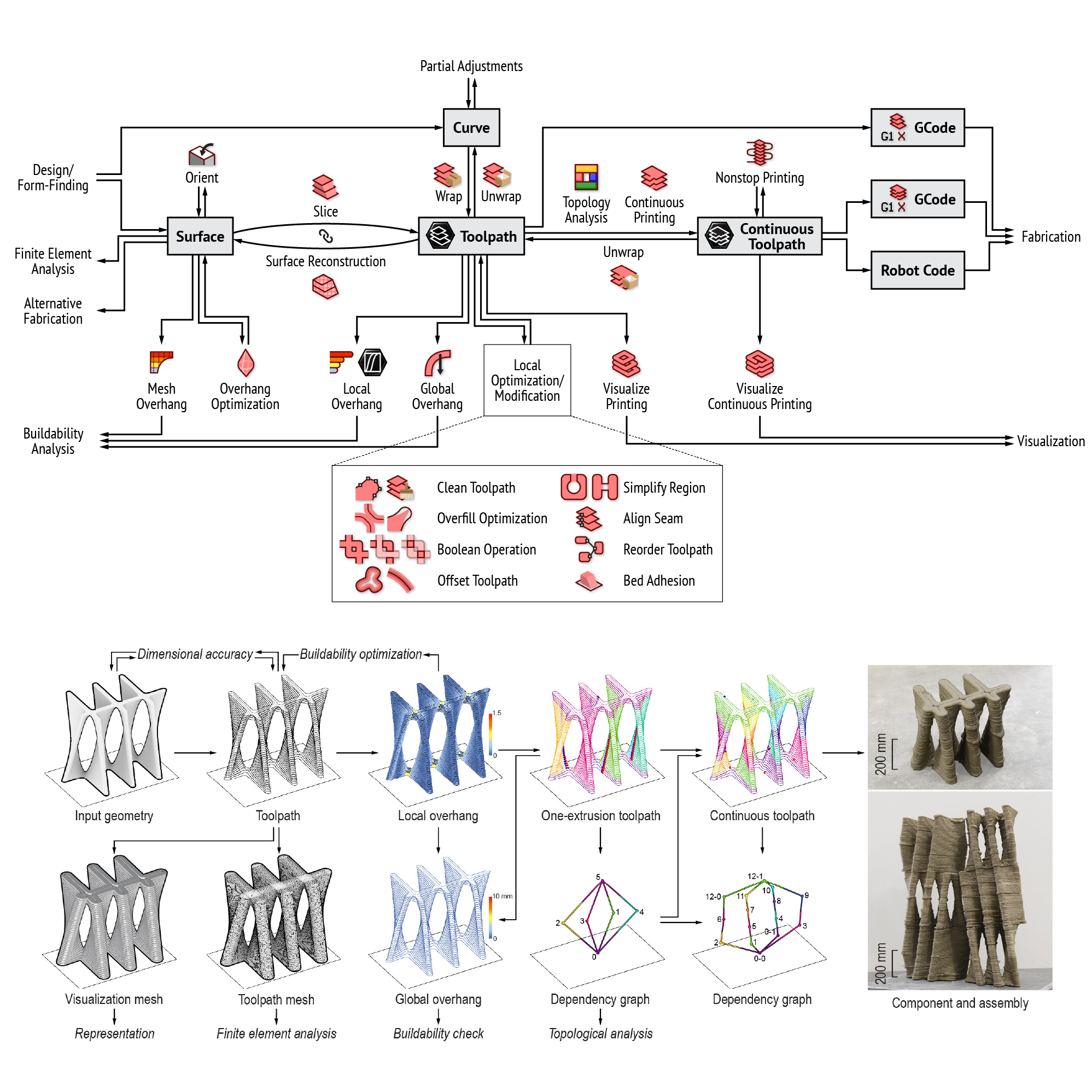

2. The following topics in toolpath design will be introduced: toolpath data structure, buildability assessment, buildability optimization, surface quality optimization, and scalability of extrusion-based 3D printing.

3. Participants will learn to generate toolpaths for 3D concrete printing with Ovenbird. They will apply optimization methods and learn to prepare files for production, simulation, visualization, etc.

4. Participants will work in groups to design a discrete structural assembly (wall, vault, etc). They will generate toolpaths for the structural components and print them as scaled fabrication models (SFM) using PLA.

Workshop description

3D-printed concrete structural components for construction assemblies are known for reduced material use, enhanced construction efficiency, and design freedom. Given the limitations in material properties and extrusion systems, an integrated approach to designing the geometry and toolpath while maximizing the advantages of 3D concrete printing would require tailored software and expertise in computing and processing geometries.

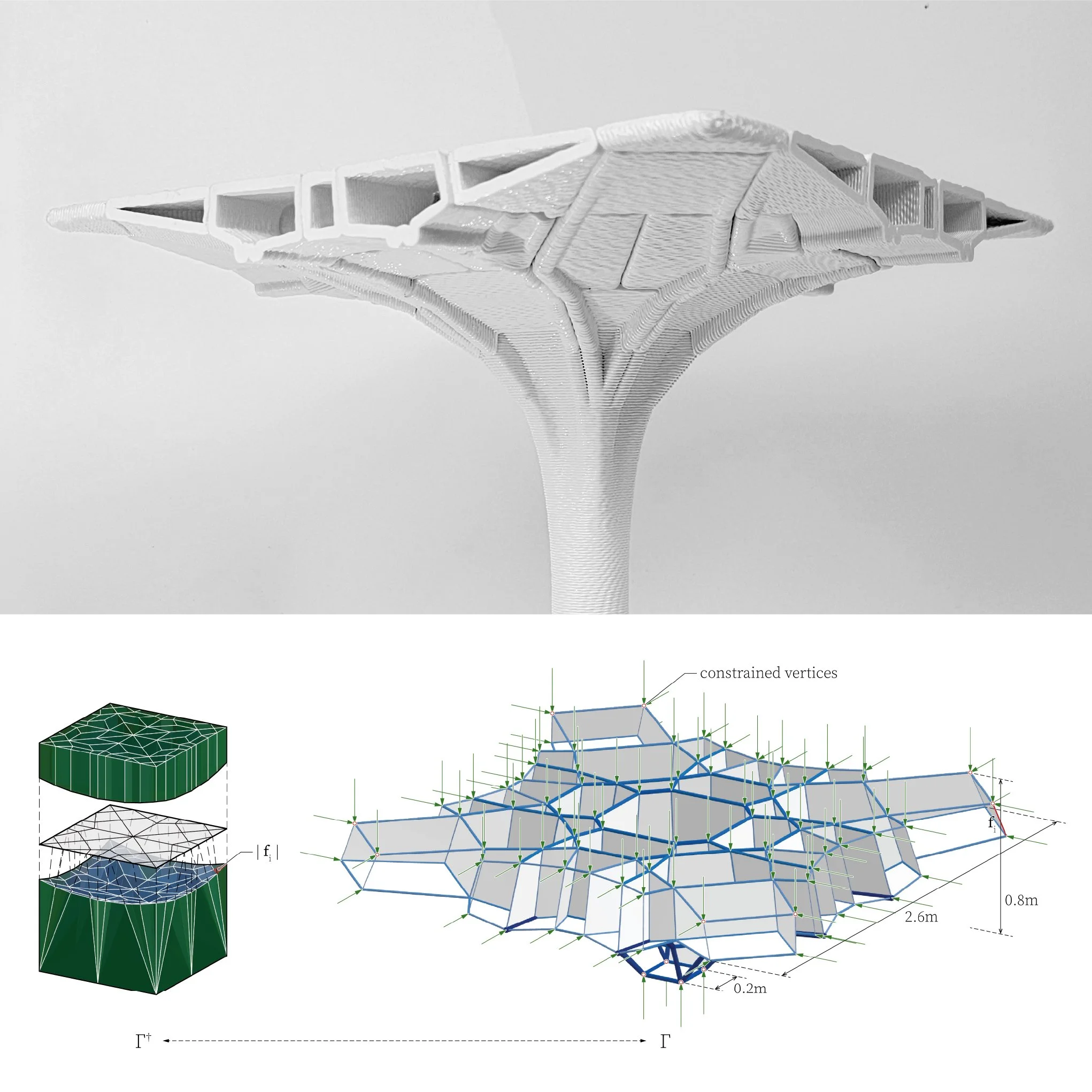

We have developed Ovenbird, a comprehensive tool that automates the task of toolpath design and optimization. (1) It assesses a component's local and global overhang, predicts failure, and optimizes its buildability as a mesh surface globally. (2) It provides toolpath optimization methods to enhance dimensional accuracy and surface quality. (3) It creates as-continuous-as-possible toolpaths with minimal stop-starts to reduce seam defects. (4) It allows the inverse reconstruction of toolpath meshes compatible with finite element analysis.

Ovenbird applies to extrusion-based 3D printing across scales and materials (clay, thermoplastic, etc.). It has powered several construction projects and benefited the 3D printing community.

The workshop will introduce participants to the theoretical and practical framework of Ovenbird. They will learn how to design printable geometries, generate optimal toolpaths, and print them as scaled fabrication models (SFM).

To help participants explore the design-research landscape of 3D-printed structures, the workshop will also introduce the form-finding method of Polyhedral Graphic Statics. Participants will study the process using Polyframe 2, another software developed at the Polyhedral Structures Laboratory. They can opt to apply Polyhedral Graphic Statics or other form-finding and design methods to prepare the scaled fabrication models to print.

Ovenbird on Food4Rhino: https://www.food4rhino.com/en/app/ovenbird?lang=en

Polyframe 2 on Food4Rhino: https://www.food4rhino.com/en/app/polyframe-2?lang=en

Paper detailing the design of Ovenbird: https://www.sciencedirect.com/science/article/pii/S2214860425000260

Paper introducing scaled fabrication models: https://link.springer.com/article/10.1007/s44223-024-00070-3

Selected projects by Ovenbird:

https://psl.design.upenn.edu/project/diamanti-3d-printed-post-tensioned-concrete-canopy/

https://psl.design.upenn.edu/project/european-cultural-centre-exhibition/

Participant Prerequisites

Participants should bring laptops (preferably Windows) with Rhino (>=7) and Grasshopper installed. They are also encouraged to bring design ideas that can potentially turn into 3D-printed concrete structures. A basic knowledge of Rhino + Grasshopper is required. A basic understanding of 3D printing is optional.

Workshop Information

Workshop Leaders

Yefan Zhi, University of Pennsylvania

Yefan Zhi is a rising third-year Ph.D. student in Architecture at the University of Pennsylvania, where he is part of the Polyhedral Structures Laboratory (PSL). His research interests include 3D concrete printing, its applications in structural systems, form-finding by graphic statics, and methods of multi-material extrusion. He is especially excited about exploiting computational geometry and graph algorithms to optimize the energy and material efficiency of additive manufacturing processes across the architecture, engineering, and construction industry. Yefan is the author of the 3D printing slicing software Ovenbird, which has powered all 3D printing research projects at PSL. Before coming to UPenn, he studied at Tsinghua University and received a Bachelor’s degree in Architecture and a Bachelor’s degree in Sociology.

Website: https://yefan-zhi.github.io/

Masoud Akbarzadeh, University of Pennsylvania

Masoud Akbarzadeh is a designer with a unique academic background and experience in architectural design, computation, and structural engineering. He is an Associate Professor of Architecture in Structures and Advanced Technologies and the Director of the Polyhedral Structures Laboratory (PSL). He holds a D.Sc. from the Institute of Technology in Architecture, ETH Zurich, where he was a Research Assistant in the Block Research Group. He holds two degrees from MIT: a Master of Science in Architecture Studies (Computation) and an MArch, the thesis for which earned him the renowned SOM award. In 2020, he received the National Science Foundation CAREER Award to extend the methods of 3D/Polyhedral Graphic Statics for education, design, and optimization of high-performance structures. He is also a Co-PI in a $4.6 million grant funded by the National Science Foundation to investigate high-performance, self-morphing building blocks across scales toward a sustainable future. He has also received a $2.4 Million ARPA-E Grant to research the design of carbon-negative buildings.

Website: https://psl.design.upenn.edu/